Heat Press Temperature Control Issues

|

Heat Press Temperature Control Issues and How to Fix ThemDo You Suffer from BTC |

| A True Story of a Customer with BTC “Mike, We have a 40×64 Geo Knight Maxi Press we use for layering materials…. (He was experiencing “water spot” type white areas, uneven color, unpredictable results – Mike).All we needed was a thermometer and some calibrations to solve tons of problems. We now have all 3 of our heat presses operating correctly, and are able to sublimate on our materials consistently with no problem. This has saved me days of trial and error and tons of scrap materials. Thanks Mike and BestBlanks for your help!” -David R. |

|

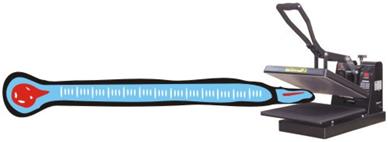

| Mike…What happened here? Their actual press temperature did not match their dial/temperature display. Sometimes this can be a few degrees. In David’s case it was more than 30 degrees low. He also had a small press that was more than 30 degrees hot! This can happen over time or can sometimes occur out of the box. Either way, periodically testing your equipment at least every 6 months is essential maintenance step. The savy customer will check their brand new press. You want to make sure your transfers are applied at the correct temperature so you are providing your customer with the best possible products. I handle many customers’ problems with their presses not reading the right temperature. This really can be very frustrating, because they seem to be doing everything right and “by the book.” |

|

| Mike…What can I do about it? There is no pill for a bad case or BTC (Bad Temperature Control), but there is a cure! Just like mom did… when you were sick or just faking it… the 1st step is to accurately take the temperature of your heat press. There are 3 ways to do this. |

|

|

Use a Digital Pyrometer & Surface Probe Kit. This is the most accurate and precise way to determine temperature. With the surface probe, fast, highly accurate temperature readings of the heat platen surface are immediately available. |

|

|

Paper Temperature test strips are an inexpensive, however less precise way to determine temperature. You close the press on these strips and they will darken in the appropriate areas to show you what is the highest temperature that they reached. Paper strips are accurate but will only get you within 10 degrees. |

|

|

IR (InfraRed) Non Contact Laser Gun thermometer do not get accurate readings from Aluminum Platens, due to the completely different Emistivity (radiating) characteristics of aluminum. With non-Teflon coated aluminum heat platens, an IR Gun reading of 100-150 degrees less than the actual platen temperature is not uncommon. It is a great way for testing final product temperatures, but not the actual heat press platen itself. |

|

|

The next step is to calibrate your press to your measured readings. Here you will consult your heat press manual or the manufacturer of your heat press. |

|